Industry 4.0: How Manufacturing Companies Can Avoid Missing Out on the Fourth Revolution

Executive Summary: The potential benefits of Industry 4.0 are profound...but only if a manufacturing company has a modern solution to integrate and automate more operational data than ever. Fortunately, we help companies with that every day.

Article

7 min read

According to IBM, the potential benefits of Industry 4.0 are profound:

At the same time, those benefits can only be realized by gathering MORE data from MORE manufacturing assets and work flows to support superior operational insights and company-wide decisions.

But what about the company whose data – no matter the amount – isn't integrated? How can having MORE information make things better?

It can't and won't.

But, as we'll see in this article, with the help of modern data integration and data automation, manufacturing companies of all sizes can leverage the benefits of Industry 4.0.

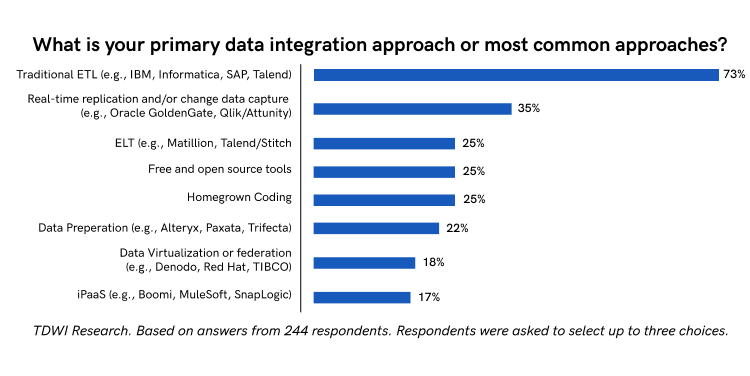

"There has never been as much pressure on data integration as there is today, with users demanding faster data flows, better performance, and access to big and increasingly diverse data. A forward-thinking data integration strategy can be the linchpin to business success." – TDWI Research, Lack of Modern Data Integration Hindering Business Objectives, Survey Finds, May 2021

IIOT REQUIRES INTEGRATION

The Industrial Internet of Things (IIOT) enables a back-and-forth conversation between your factory floor or production facility on the one side and your apps and data flows on the other.

Whether data is gathered through sensors on machines, embedded software, or any other modern mass production tech, IIOT is all about connecting real-world manufacturing assets with digital-world technologies.

IIOT is a pillar of Digital Manufacturing.

"Digital manufacturing technologies link systems and processes across all areas of production to create an integrated approach to manufacturing, from design to production and on to the servicing of the final products."

-TWI Global

The more data you can gather, the more informed your decisions can be. Better yet, the more automated your processes can become.

But without integration, IIOT becomes a tangled and squandered collection of siloed data points.

Which is why data integration and data automation are so important. That's how manufacturing companies can:

- Tie all their data together

- Keep it clean, consistent and free of errors

- Provide a way to easily deliver data to internal users

GETTING DATA TO USERS REQUIRES INTEGRATION

In a recent TDWI Research study, they asked companies about their experiences with getting new data sets to data consumers in the organization.

66% of Respondents Said

They submit a request to IT, the Business Intelligence team, or another centralized group

(TDWI referred to this approach as "the old-fashioned way")

77% of Respondents Said

IT can't keep up with internal user requests for data

Only 20% of Respondents Said

They were getting data themselves using SQL and technical tools

Some companies do not have solutions in place to easily deliver data to internal users due to working with legacy or technically-challenging systems.

In other cases, data security and governance policies are factors that hinder easy access to data.

In either case, modern data integration solutions can make data management and data access both easy and secure while also automating repeated processes and data reporting across the company's work flows and divisions.

And in the world of Industry 4.0, it's not only humans that need efficient access to data but also your manufacturing assets on the factory floor and workflow systems throughout the company. That level of system-wide data sharing is essential if manufacturers want to fully leverage their ability to automate processes and machine logic.

SUPPLY CHAIN MANAGEMENT REQUIRES INTEGRATION

"Smart manufacturing" doesn't only involve high tech gadgets on the factory floor or in the IT department.

It encompasses most divisions of today's modern manufacturing company, including Supply Chain Management (SCM).

After all, SCM itself encompasses most of the typical workflows and systems of a manufacturing company.

It's not uncommon for a company's Supply Chain Management umbrella to cover:

- Sourcing/Procurement

- Production

- Inventory (internal and vendors/suppliers)

- Marketing

- Sales

- Shipping/Distribution/Logistics

- Returns

- Information systems

- And more

That wide scope makes SCM a very large undertaking at the best of times.

But it also means SCM represents many opportunities to realize improvements in efficiency and data management that can significantly move the needle in your organization.

"With so many places along the supply chain that can add value through efficiencies or lose value through increased expenses, proper SCM can increase revenues, decrease costs, and impact a company's bottom line."

– Investopedia

That's why data integration and data automation are needed to enable all the apps, data nodes and systems across a manufacturing company to talk together seamlessly while preserving data integrity.

Under an Industry 4.0 approach to Supply Chain Management, data management goes beyond the walls of your company. By sharing select production data with suppliers, manufacturers can schedule deliveries more efficiently, such as rerouting or delaying deliveries in the case of an assembly line disruption.

Agile processes of this sort require modern data integration and data automation if a company expects to realize the full efficiencies and cost reductions that Industry 4.0 offer.

"Full realization of smart manufacturing demands connectivity and integration of engineering, supply chain, production, sales and distribution, and service."

– IBM, How Industry 4.0 technologies are changing manufacturing

Learn more about Data Integration & Supply Chain Management, How CIOs Can Boost Clarity & Efficiency Through Digital Transformation

DOING BUSINESS REQUIRES INTEGRATION

"Data integration can be a source of frustration when there are too many delays, too much inflexibility, and chaos brought on by data integration silos that bring inconsistency and inefficiency. However, this means that data integration modernization can have a big impact."

Under normal circumstances, general business objectives are easier to achieve when a company's data is integrated.

Under Industry 4.0, with its increased amount of data, modern data integration and data automation are more important than ever to increase efficiency and speed, reduce costs, and improve decision making.

Which raises the question: What is the best modern approach for data integration and data automation?

iPaaS (Integration Platform as a Service).

iPaaS is a tech platform that a third-party company usually provides through the cloud to help companies integrate and automate their apps and data.

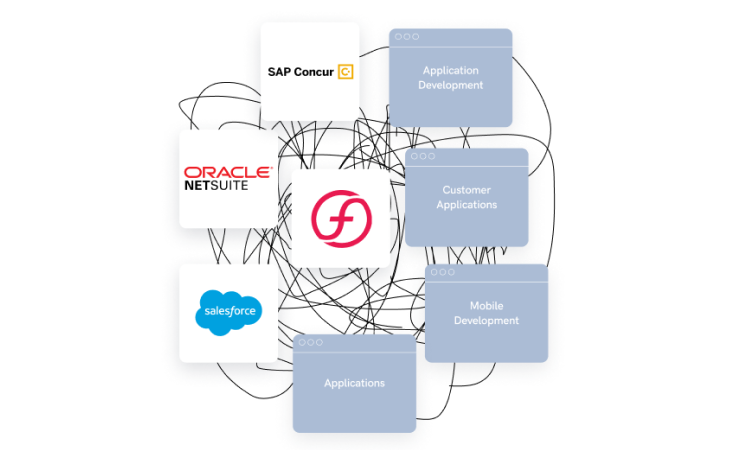

The old-fashioned, inefficient approach to integration is creating one-to-one connections between data nodes, like in the diagram below:

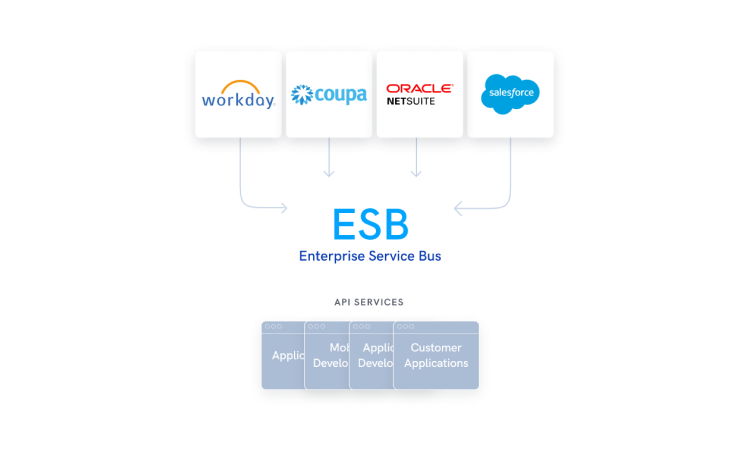

In contrast, the better alternative is how we do iPaaS at Launchpad: through a modern Enterprise Service Bus (ESB) architecture.

With an ESB model, you gain the advantage of having connectivity from any and all of your apps through a central intermediate ESB layer, like in the diagram below.

With an iPaaS ESB model, when any of your apps need access to a piece of data, you don't have to create (or recreate) another data connection. Instead, everything gets routed through your ESB layer.

That means you have superior data access and management but with less connections, which increases your efficiency and lowers your operating and development costs.

You can even leverage existing connectors, such as the 400+ pre-built connectors available through Launchpad's PaasportTM Integration Platform.

Increasing your efficiency through less connections is only one of many reasons why iPaaS is the best technology today for data integration and automation.

Learn more about iPaaS from our blog article, 4 Reasons to Use iPaaS for Data Integration.

Better yet, with Launchpad you don't have to try to figure out yet another technology. Our team of experts will plan, configure and manage your enterprise-grade integration from start to finish on our PaasportTM iPaaS platform.

“Launchpad’s team guided our transformation project to success through their expertise and knowledge of industry best practices."

– SAFE SOFTWARE

SUMMARY & NEXT STEPS

Manufacturing companies of all sizes can leverage the benefits of Industry 4.0:

More operational data to work with

Back-and-forth conversation between factory floor and apps/data nodes

Superior operational insights and company-wide decisions

But to make that possible, companies also need modern data integration and data automation.

We help companies with that every day. Our specialty is providing worry-free integrations that are fully managed and hosted so you can free up your team to focus on what they're best at.

About Launchpad

We Integrate Your Apps. You Scale Freely.

We provide next-generation integration platform capabilities and custom integration services for connecting and managing enterprise automation and data integration.

Get your integration started – contact us today.

1.800.326.0188 | info@golaunchpad.io

Try Launchpad risk-free

Transforming your integrations is easier than you think. Get started quickly with us.

- ©Launchpad 2024

- Privacy Policy

- Support