Supply Chain 4.0: Five Key Questions Answered For Manufacturing Companies

Executive Summary: Yesterday's supply chain reality has been disrupted...but Supply Chain 4.0 enables manufacturing companies to adapt to new demand patterns, logistics bottlenecks and the need for real-time data-driven decision making. Read "Five Key Questions Answered For Manufacturing Companies".

Article

8 min read

"Increasing competition, speed to market, and the ability to shift from being a supplier to becoming a solutions provider make digital supply chains essential."

– IBM's Institute for Business Value

Supply Chain Management is the backbone of any manufacturing company.

But when asked by IBM, only 37% said they were effective at supply chain requirements.

There's clearly a need for improvement, especially in the face of the disruption of the traditional supply chain environment due to:

New demand patterns creating extreme volatility of inventories

Logistics bottlenecks due to lack of transport, warehouse space, and last-mile solutions

Increased pressure from inside and outside the organization to operate sustainably

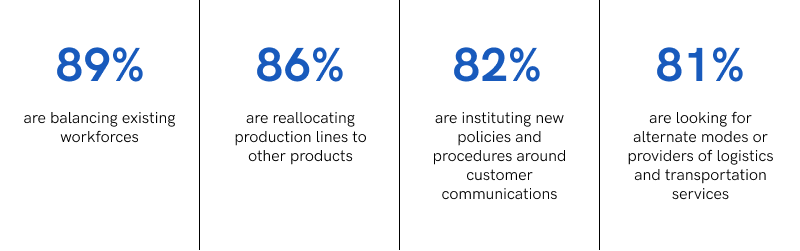

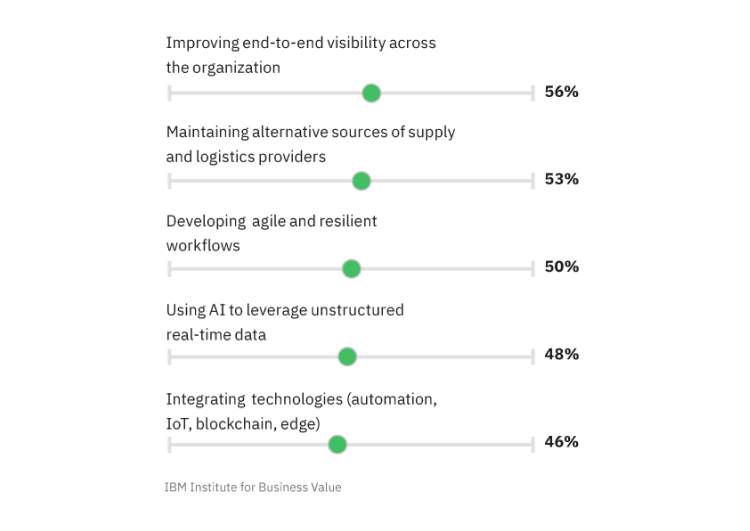

It's no surprise then that supply chain executives are trying various strategies in an effort to adapt to today's new supply chain reality:

It's also no surprise that manufacturing companies are looking into Supply Chain 4.0 as a company-wide, systematic alternative to yesterday's insufficient supply chain management model.

Since efficient supply chain management is a top goal among the manufacturing clients that turn to Launchpad for data integration and automation solutions, we've prepared this article to answer five key questions related to Supply Chain 4.0:

What is Supply Chain 4.0?

Is it worth the effort?

What's required to enhance performance company-wide?

Why the extra emphasis on customer experience?

What's the best place to start?

QUESTION #1: WHAT IS SUPPLY CHAIN 4.0?

Supply Chain 4.0 is related to Industry 4.0.

Industry 4.0 involves connecting real-world manufacturing assets with digital-world technologies. This advanced manufacturing model increases company-wide insights, enables responsive automation, and improves decision-making abilities.

Back-and-forth conversation between your production facility and your apps/data flows is made possible through advanced real-time data that's gathered through sensors on machines, embedded software, or any other modern mass production tech.

Supply Chain 4.0 is a digital transformation strategy that's a natural extension of Industry 4.0.

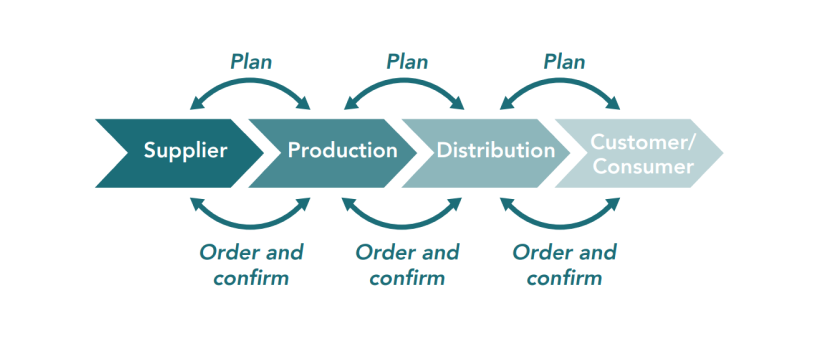

It involves advanced data gathering technologies and supply chain digitization, but also a non-linear supply chain approach that offers the benefits of an end-to-end, insight-driven model.

The diagrams below help visualize how the old supply chain model differs from Supply Chain 4.0.

The Traditional Linear Supply Chain Model

The Supply Chain 4.0 Model

The key takeaway from the Supply Chain 4.0 diagram above is the prevalence of real-time data-driven interconnectedness and feedback from the company and its partners, suppliers and customers.

"The digital supply chain leapfrogs an antiquated model."

– IBM's Institute for Business Value

Which is why a digital supply chain enables:

Greater transparency

Advanced planning

Dynamic prediction of demand patterns

Improved ability to customize orders

Leveraging of asset availability

"The more broadly technologies are deployed — from raw material extraction and sourcing to refinement, manufacturing, shipping, and sales — the better-positioned companies will be to compete over the longer term."

– Forbes, Nov. 2021

QUESTION #2: IS IT WORTH THE EFFORT?

Before we answer question #2, let's take a moment to outline the alternative to Supply Chain 4.0, which commonly involves:

Manual tasks that are slow and prone to errors

Spreadsheets that are disconnected and cumbersome

Siloed apps that are recipes for introducing data inconsistencies

On top of that, there are the limitations of the linear model seen above that fails to provide an end-to-end, real-time understanding of your company's supply chain bottlenecks and opportunities.

In contrast, Supply Chain 4.0 has real-world business cases and numbers to back up its value to a modern manufacturing company.

According to IBM, a digital supply chain can lead to the following significant business outcomes:

On a more specific level, IBM's research also found that:

76% of organizations furthest along in digitizing their supply chains were effective at improving speed, reliability of manufacturing, and distribution

69% of leading organizations had realized significant ROI from investing in predictive analytics for the supply chain

These types of improvements are extremely desirable, especially when viewed against the chaos created by COVID-19. The pandemic revealed supply chains to be inflexible and unable to quickly respond to shifting inventory scenarios, demand patterns, and supplier availability.

In contrast, a digital supply chain dynamically predicts demand pattern shifts while increasing a company's overall data and asset visibility.

In summary, the Global Head of Enterprise Marketing at Nokia, Rahul Aggarwal, answers the question "Is it worth it?" this way:

"Digital transformation is increasingly seen as essential to ensure adaptability and resilience through automation and greater data-driven intelligence."

QUESTION #3: WHAT'S REQUIRED TO ENHANCE PERFORMANCE COMPANY-WIDE?

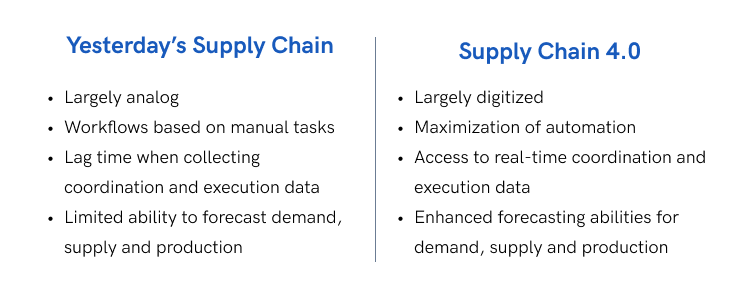

The stark contrast between yesterday's supply chains and Supply Chain 4.0 can be made more evident through a side-by-side comparison:

The list above for Supply Chain 4.0 makes it easy to understand how the model supports enhanced performance company-wide.

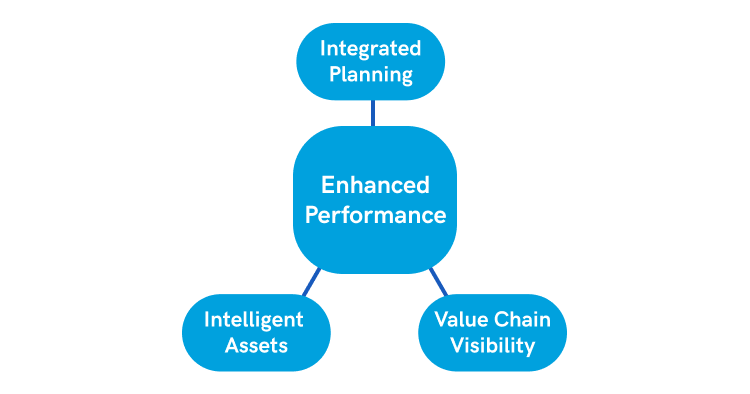

For a manufacturing company to realize that performance enhancement, however, there are 3 capabilities needed:

Integrated planning involves greater alignment of business divisions to enable faster decision making and adaptation.

Value chain visibility involves end-to-end data access to enable real-time reporting and to help identify risks and supply disruptions.

Intelligent assets include modern mass production technologies that provide greater insight into the factory floor and manufacturing process.

According to IBM, when these 3 capabilities combine to support a digital supply chain, manufacturing companies can experience enhanced performance in the following ways:

Optimized inventory

Reduced logistics costs

Higher customer fill rates

Reduced operating costs

Incremental revenues

New market opportunities

It's important to note that, before a company can benefit from integrated planning, value chain visibility and intelligence assets, they will need a modern data integration and automation solution to handle the increased amount of data involved. We will revisit this need in Question #5.

QUESTION #4: WHY THE EXTRA EMPHASIS ON CUSTOMER EXPERIENCE?

When learning about Supply Chain 4.0, customer experience is often front and center.

This extra emphasis is largely due to the need for manufacturing companies to understand and respond to the unique nature and demands of modern customers.

"Today’s customers are better informed, better connected and more demanding than ever before. The supply chain must adapt to these heightened expectations."

-KPMG: Future of Supply Chain

Adapting supply chains to meet these heightened customer expectations requires:

Gathering new types of external data to inform supply chain management (e.g., weather forecasts) and manufacturing decision making (e.g., social media comments from customers)

Gathering new types of internal data from smart manufacturing sensors to ensure production and delivery schedules stay on track to meet consumer orders

According to KPMG, reliably fulfilling customer expectations today requires tighter company-wide integration, from product development to manufacturing, packaging, logistics and order fulfillment, which Supply Chain 4.0 is ideally suited to support.

"Customers have almost infinite product choices and near-instant delivery. This notion of customer experience must be a core tenet of your supply chain operating model."

-Brian Higgins, Principal, Supply Chain and Operations Practice Leader, KPMG in the US5

QUESTION #5: WHAT'S THE BEST PLACE TO START?

We now have a good understanding of the definition, benefits, elements and end goals of Supply Chain 4.0.

Our final question involves the desire for a roadmap to help companies transition from yesterday's model to a modern digitized supply chain model.

Since every company is unique, different supply chain executives address the process of modernizing their supply chain operations in different ways:

But regardless of where you intend to start, it is vital to understand your organization will first need a modern data integration and automation solution in place.

That is the only way you will be able to get all your data sources and apps talking seamlessly while making it easy for meaningful and accurate data insights to be accessed across your company.

In the same way that yesterday's supply chain management approach is no longer up to the task of modern business, yesterday's approach of data management is also no longer up to the task.

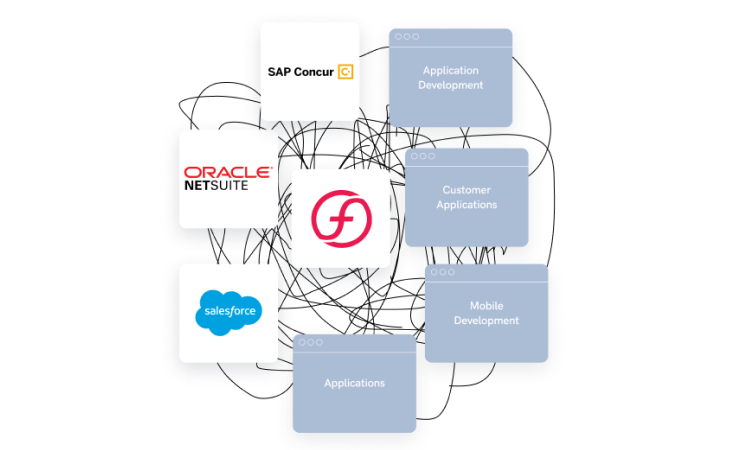

Yesterday's approach looks like the diagram below, where companies try to integrate their apps, workflows and supply chain by creating one-to-one connections:

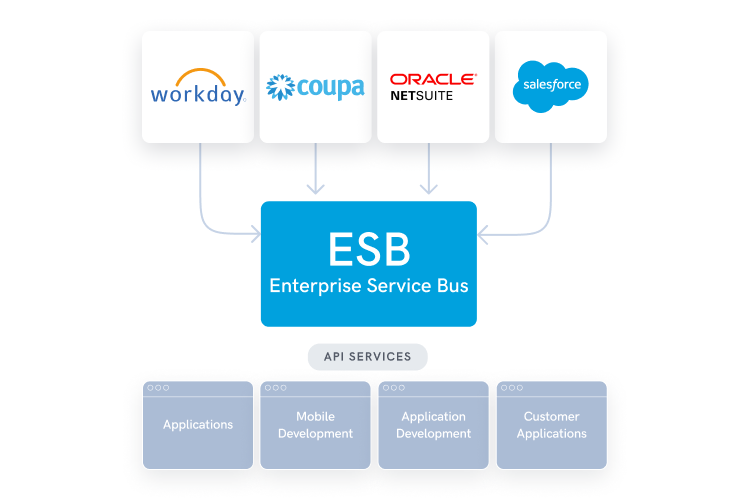

In contrast, the better alternative is how we do it at Launchpad: through a modern iPaaS (Integration Platform as a Service) Enterprise Service Bus (ESB) architecture.

With an ESB model, you gain the advantage of having connectivity from any and all of your supply chain data inputs, apps and workflows through a central intermediate ESB layer, like in the diagram below.

With an iPaaS ESB model, when any of your people or systems need access to a piece of data, you don't have to create (or recreate) another data connection. Instead, everything gets routed through your ESB layer.

That means you have superior data access and management but with less connections, which increases your efficiency and lowers your operating and development costs.

You can even leverage existing connectors, such as the 400+ pre-built connectors available through Launchpad's PaasportTM Integration Platform.

Better yet, with Launchpad you don't have to try to figure out yet another technology. Our team of experts will plan, configure and manage your enterprise-grade integration from start to finish on our PaasportTM iPaaS platform.“Launchpad’s team guided our transformation project to success through their expertise and knowledge of industry best practices."

– SAFE SOFTWARE

Supply Chain 4.0 requires a company to have superior data management because it involves supporting:

more data input sources

more data points

more data-driven insights

more cross-company data access

As a result, the answer to the question "What's the best place to start?" is to first get a modern data integration and automation solution in place.

SUMMARY & NEXT STEPS

Supply Chain 4.0 is the modern response to the disruption of yesterday's supply chain reality.

Between its advanced data gathering technologies and end-to-end data-driven model, Supply Chain 4.0 offers manufacturing companies real-world supply chain solutions.

But before companies can realize the performance enhancements that Supply Chain 4.0 makes possible, they also need modern data integration and data automation to manage the extra data involved.

We help companies with that every day. Our specialty is providing worry-free integrations that are fully managed and hosted so you can free up your team to focus on what they're best at.

About Launchpad

We Integrate Your Apps. You Scale Freely.

We provide next-generation integration platform capabilities and custom integration services for connecting and managing enterprise automation and data integration.

Get your integration started – contact us today.

1.800.326.0188 | info@golaunchpad.io

Try Launchpad risk-free

Transforming your integrations is easier than you think. Get started quickly with us.

- ©Launchpad 2024

- Privacy Policy

- Support